Tag: Daytona

The Daytona: April 23, 2008

by Russ Knize on Apr.23, 2008, under Daytona

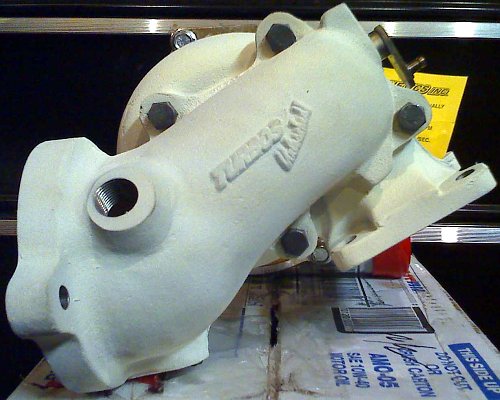

Still my daily driver. Been collecting some odds and ends that should hopefully help the spool department: A Turbos Unleashed cast log header and Turbonetics T03/T04E hybrid single ball bearing turbo with a “Super 50″ compressor and a Stage II exhaust turbine in a .63 A/R housing attached to a Turbos Unleashed 3” swing valve (whew). The header, housing, and swing valve are all ceramic thermal coated to keep temps down and gas velocities high. The turbo flange on the header is larger than it should be, so I will likely need to port the housing flange somewhat.

The Super 70 and ported exhaust manifold that is in there now will end up in the CSX once I get a new cylinder head for it. Trouble is the CSX needs to be running before I put this setup in there….

The Daytona: June 5, 2007

by Russ Knize on Jun.05, 2007, under Daytona

Drove the car all winter and spring without any major issues. The most annoying thing that happened was when the adjustable cam sprocket came loose and the car wouldn’t start late at night in the parking lot at work. I was able to snug it up with some vice grips and get home. I’ve got a stock sprocket on there now.

I recently replaced the stock headlamps with a Hella H4 “Free Form” conversion kit and built a relay module so that the lights got power directly from the battery. I measured an over 3.5V drop through the stock headlight circuit. The housings are DOT approved and I am using the standard 65/55W bulbs. The light pattern is much better than a standard sealed-beam lamp and they run nice and bright with the extra voltage. If you are thinking about a HID conversion for better visbility (and not because you think they are pretty), do the H4 conversion and relay mod instead. The on-coming drivers will thank you (I hate HIDs).

The Daytona: November 8, 2006

by Russ Knize on Nov.08, 2006, under Daytona

The stupid cheesy plastic draincock on the brand new radiator broke on the way to work. Stuffed a rag in the hole and limped back home. What a crappy design. Anyway, I did a few other odds and ends while I was at it, including the installation of the correct throttle cable. I also got the interior all cleaned up nice and managed to take some pics of the inside and the outside (it’s a little dirty on the outside, but oh well).

I’m really happy with how the guage pod and mounts turned out.

The Daytona: November 6, 2006

by Russ Knize on Nov.06, 2006, under Daytona

Drove it around a bit over the weekend. Took it to work today and romped on it a bit. The Super 70 is a bit more laggy, but it’s not anywhere near as bad as I thought it might be. Also, the intake temps are just a few degrees above ambient…this intercooler is the bomb. It’s pretty peppy even when the turbo is lagging and man this sucker moves when the boost hits. It will be interesting to see how it works once I start cranking it up. Right now it’s on the stock cal with the fuel pressure turned way down. It won’t go low enough in vacuum, so it makes it a little lean further up the scale since the autotrim gets a little out of whack. It’s like 10.5:1 at WOT, but if I leave part throttle it HAULS.

The Daytona: November 3, 2006

by Russ Knize on Nov.03, 2006, under Daytona

Finished hooking up all the guages, mounting the guage pods, getting the exterior all lined up, and getting it on all fours. Had to shorten the hood vent tray to clear the intake manifold. Also did a little fixup on the fenders, since the 87 put the belt moulding above the belt line, while the 86 has it just below the line. Did a little creative tie-wrapping to get the early throttle body cable to work on the blow-through throttle body.

The Daytona: October 29, 2006

by Russ Knize on Oct.29, 2006, under Daytona

It’s alive!!! Frankentona lives again! Got the motor all hooked up tonight, pressurized the fuel system, and checked for leaks. Stared at it for a minute to make sure I didn’t forget anything really important and cranked it over. It fired right up on the first try. I was a little surprised, given the major harness surgery it underwent in the engine bay. It was smoking pretty good from all the oil and grease on the exhaust/turbo, but it didn’t really show up in the picture. Before test firing it but after putting oil in it, I primed the system with a drill on the intermediate shaft and made sure the turbo was getting oil.

It’s alive!!! Frankentona lives again! Got the motor all hooked up tonight, pressurized the fuel system, and checked for leaks. Stared at it for a minute to make sure I didn’t forget anything really important and cranked it over. It fired right up on the first try. I was a little surprised, given the major harness surgery it underwent in the engine bay. It was smoking pretty good from all the oil and grease on the exhaust/turbo, but it didn’t really show up in the picture. Before test firing it but after putting oil in it, I primed the system with a drill on the intermediate shaft and made sure the turbo was getting oil.

All that’s left is to put the fenders and nose back on, cut down the hood vent tray, and straighten up a few things in the interior. The goal was to have it running by Halloween, but I may even have it on the road by then! Just in time too, as the CSX is starting to smoke a bit more….

The Daytona: October 27, 2006

by Russ Knize on Oct.27, 2006, under Daytona

It’s been a rough couple of weeks at work (70-80 hours), but I managed to get some garage time in. The exhaust installation is complete. It came out pretty good, but I had the usual surprises. The FWD Performance kits really like the passenger side. The exhaust on both the Daytona and CSX had about 1/2″ too much length between the two 90 degree bends, which pushes the cat up against the heat shield from the back. I had to remove that amount from both, but I had to cut that pipe anyway to swing the back half up a bit. It’s clamped for now, but I will weld it once I’m happy with how the exhaust has settled in its hangers. Add to that the 3″ down pipe, which doesn’t have enough length before the last curve and the cat ends up rubbing the heat shield. Some heat shield massaging was needed to clear it. The missing down pipe heat shield required that I wrap the down pipe in header wrap and shield the shifter cables a bit. The offset oval muffler simplified the cutting/fitting behind the muffler, since I could use the offset to drop the tail pipe. That part worked out well.

I’m not really happy with the Walker stainless band clamps. They are nicely made and have captive nuts (which will be interesting once they are nice and rusty), but they don’t seal really well due to the way they pull up on the band where it is welded to itself. The cheaper clamps that are on the CSX (Jegs/J.C. Whitney) seal better and I like how they “take-up” the band slack in the dished grooves.

The Daytona: October 15, 2006

by Russ Knize on Oct.15, 2006, under Daytona

Stupid skin infection came back again…grrr. Really slows me down, but I did get the bobble strut mount from Johnny welded to a backplate and welded to the K-frame. Man, I suck at stick welding. At least with the MIG, the tool helps mask my poor skills. Anyway the mount that Johnny sells is very solid. However, it is being welded to stamped sheetmetal on the K-frame and the contact patch is only about one square inch. As such, a transitional plate is needed to spread the load over a wider area on the K-frame to prevent cracking. I made mine out of a couple of scraps of 1.5″ angle iron that was cut, bent, hammered, etc until it matched the profile of the K-frame.

Stupid skin infection came back again…grrr. Really slows me down, but I did get the bobble strut mount from Johnny welded to a backplate and welded to the K-frame. Man, I suck at stick welding. At least with the MIG, the tool helps mask my poor skills. Anyway the mount that Johnny sells is very solid. However, it is being welded to stamped sheetmetal on the K-frame and the contact patch is only about one square inch. As such, a transitional plate is needed to spread the load over a wider area on the K-frame to prevent cracking. I made mine out of a couple of scraps of 1.5″ angle iron that was cut, bent, hammered, etc until it matched the profile of the K-frame.

I also got the exhaust cut and fitted. Had to make the same basic changes to the back half as I did on the CSX. Also, getting the nut on the driver’s side down pipe bolt is problematic when using the TU 3″ swingvalve with the .63 A/R exhaust housing. More on that when it is done.

The Daytona: October 9, 2006

by Russ Knize on Oct.09, 2006, under Daytona

Got the clutch and did the swap. Also got the intercooler perminently installed after painting the core support. The TU ceramic/organic clutch (left) is headed to the CSX. The Kevlar clutch (right) is installed, along with its sparkly blue painted Sachs pressure plate.

The Daytona: October 3, 2006

by Russ Knize on Oct.03, 2006, under Daytona

A nasty skin infection has kept me out of the garage for a couple of weeks, but I did manage to paint all of the welded areas on the core support and the new intercooler-related bracketry. I also welded lips onto the intercooler pipes by carefully tacking 1/16″ stainless steel rings make from rod stock onto the edges. My initial plan was to roll beads into them with a Harbor Freight bead roller that I got on sale. Well the rollers were too large to fit into the tubes, so that didn’t work. I was going to try to have different rollers made, but it wasn’t worth the effort.

The issue I was having at the track with the clutch in the CSX was a good reality check that this LUK T3 clutch isn’t going to hold. I had purchased a TU “Dual Performance” ceramic/organic clutch for this powertrain, however I found that I accidentally ordered the early small spline version (the small shaft has 18 splines, while the large shaft has 17 splines). I had a new T3 disc kicking around, so I just tossed that in instead. I’ve ordered a TU Kevlar clutch (appears to be a Clutchnet clutch disc) that should hold well. It has a little less holding power than the ceramic puck discs, but I should get much better mileage out of it. The 6-puck that I had in the CSX before was shot after about 30k. It sucks to have to drop the trans again, but it’s a lot easier now than it will be when it is all buttoned-up and covered in the inevitable grease.