CSX

The CSX: July 7, 2000

by Russ Knize on Jul.07, 2000, under CSX

After dealing with all kinds of problems with paint on that fender, I finally got the car ready. The doors are back together and everything is installed. One of the power door lock motors was frozen, so I will have to find another. I even had time to paint the upper door trim and the mirrors to match the new lower trim pieces a bit better. I also resealed the valve cover and got the A/C working (just this evening). All I need to do is wash the car tomorrow and take off!

The CSX: June 16, 2000

by Russ Knize on Jun.16, 2000, under CSX

The car has been sitting for a very long time. I started working on the rust on the left, front fender a few weeks ago. The Shelby Dodge Automobile Convention 10 is coming up in July 8, so I am starting a campaign to get the car ready. I need to get the power window and door lock motors installed, as well as the power mirrors (the doors are already taken apart). I also need to replace the weather stripping along the bottom of the door windows. Mechanically, the car is sound. I would like to have air conditioning for the trip as well, so I will pull the A/C heater unit to flush the crud out of the evaporator coil (the compressor was rusting, internally). I will replace the plugged heater core while it is out.

I’ve signed-up for all the events, which includes a performance driving school and drag racing. I won’t bother with the car shows. 🙂 The car is going to take a beating, so hopefully it will be able to make the trip there and back.

The CSX: October 19, 1999

by Russ Knize on Oct.19, 1999, under CSX

A few more weird things happened lately. First the long, steel fuel line on the fuel rail cracked at one of the bends, causing the rail to depressurize when I accelerated. Then I started getting very bad hesitation. it got to the point where the engine would not even want to run under any load, then would suddenly be fine. Turned out to be the ignition coil mounting bolt, which was stripped out. Now all is good and the car is flying.

The next thing that needs attention is the tires. There appears to be flat spots from a 4 wheel lockup (panic stop). It has been doing this since I bought the car. I’m not sure if the tires can be salvaged, but the vibration is very annoying at high speeds.

The CSX: October 12, 1999

by Russ Knize on Oct.12, 1999, under CSX

For the first time in a while, less bad news. 🙂 I finally got the Conquest intercooler installed last week. I found some 90-degree 2-1/8″ I.D. hoses for the connections under the front cross member. I found them at Trak Auto for some kind of Ford van. The rest of the plumbing consists of mandrel-bent and straight exhaust pipe. The turbo-to-intercooler run is two 2″ mandrel bent pipes and some straight hose. The intercooler-to-throttle body run is two 2-1/4″ mandrel bent pipes and a long 2-1/4″ straight pipe. All connections were made with bits of truck radiator hose and many stainless hose clamps.

Now that this car is intercooled, I return boost control back to the logic module. So now the 16psi ND computer can do it’s thing. No more pinging at 13psi either. While I was at it, I relocated the MAP sensor to the firewall right next to the brake booster. I made an aluminum heat shield to protect the sensor and solenoids from the turbo. I took great care in replumbing the vacuum lines such that critical sensors will not be effected by other vacuum devices. These include the MAP sensor and fuel pressure regulator. Now the funky fuel curve problem is gone.

The setup worked great for about a week until I started getting problems where the engine would QUIT just as I would start to accelerate. I also noticed an erratic idle speed. I have have always had a code 15, so I just unplugged the frickin’ speed/distance sensor–problem solved. I don’t have cruise, an automatic, or electronic speedometer, so the usefulness of the sensor is questionable anyway.

In other news, the piston slap is as bad as ever and the engine is consuming oil, though I don’t notice any smoke or smell at all, nor do I see any in the coolant, etc. I loose about a quart every 1000-2000 miles. I’m sure it’s just the rings. Blow-by is horrible…the dipstick isn’t blowing out, but it is very tight in the tube. Oil is coming out of the oil cap and it just recently blew some RTV out of the valve cover seal. Due to the Shadow’s current condition, the Shelby is now my daily driver. I hope it holds up….

The CSX: September 22, 1999

by Russ Knize on Sep.22, 1999, under CSX

Well, the weekly strife with this car continues. Monday it barfed out the block core plug behind starter…it had rusted out from the inside. I replaced it with a expanding rubber core plug (Expand-Tite), which seems to be holding. The next plug down has some evidence of a very slow leak. Looks like that one is next.

The piston slap is slowly getting worse. I think I should start thinking seriously about building-up a new, solid bottom end for this thing. No screwing around this time…. *sigh*

The CSX: September 17, 1999

by Russ Knize on Sep.17, 1999, under CSX

Still no leaks, trans fluid, coolant, or otherwise. The tires are severely out of balance or out of round. I will try to get them balanced. That metal-to-metal squeak turned out to be my 2.5″ exhaust rubbing on the rear axle cross members. That Dynomax muffler is very heavy and it has stretched the stock mount.

Other than that, the car needs new ball joints and outer tie rod ends (boots are gone). A new set of bushings will probably be good too. I may just try to find a ’89+ K-frame and put the new ball joints and polyurethane bushings right on it.

The CSX: September 15, 1999

by Russ Knize on Sep.15, 1999, under CSX

Well, I wanted to get started pulling the trans last night. This is the first time I got near it since I discovered the left side of the trans, axle, and engine bay covered in trans fluid on Saturday. I jacked up the car and grabbed the axle. It was not sloppy at all, compared to how it was before I installed the stabilizer bearing. Then from the topside, I noticed trans fluid all over the TOP of the trans as well. It appeared to be coming from the top of the shifter plane (slider) selector lever. There is a plastic cap on the shaft, which I assume is the gear case vent (it’s not on the bearing retainer plate like on the A525/A520/A555). I am in the habit of overfilling my trannies by about 1/2 quart. It works fine on the A520s. On the A568, it seems to puke the extra oil out. The oil would run into a webbed area of the top of the trans, fill it up with oil, then it would run down the side, right over the left-side axle. It appears that this is where the oil is coming from. I cleaned the whole thing up with acetone so that it is dry and drained the excess fluid from the case (it was still very high). I then proceeded to address a coolant leak from that stupid head (helicoils). I may just have lucked out.

I fixed the coolant leaks at the thermostat housing by using the solvent-safe PFTE thread tape with Master #2 Gasketmaker (not RTV, this stuff stays soft). It appears to be holding up just fine.

I have no doubt that this tranny needs to at least have the diff re-shimmed. Perhaps even new spiders. But, it looks like it may be salvageable otherwise. The stabilizer bearing appears to be doing its job.

The CSX: September 13, 1999

by Russ Knize on Sep.13, 1999, under CSX

It appears that the stabilizer bearing has self-destructed. On the way home from the SDACCL meeting on Saturday, I started to notice a sort of vibrating metal-to-metal squeak that was getting louder and louder. When I got home I found the entire left side of the tranny covered in oil. I guess the bearing just can’t handle it. So, it appears that I will be looking for a replacement differential.

Before the meeting I was able to install the new “Jessie Buhr” 2-1/2″ aluminized exhaust system (thanks Mark!). The fit was mediocre at best and some bending and cutting/rewelding was required. It’s still a bit off, so I will have to make some tweaks to it. Aside from that, it is a nice system. The original 2 1/4″ exhaust with no muffler droned way too much when cruising. So, I opted for a Dynomax Super Turbo muffler (part# 17710). It’s a nice unit and is the perfect length to fit in a P, J, or G-body. It’s a 7″ round, 18″ long unit. It has a nice sounding idle and seems to be quite good at the top end. Not as good as an open pipe, but good enough for me.

The CSX: September 10, 1999

by Russ Knize on Sep.10, 1999, under CSX

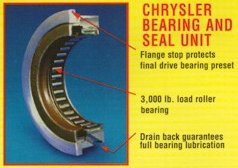

I believe that I have found a “patch” for my current transmission problems. Thanks to Joe Dzwil, I was able to install a Techpak-Fitzall Chrysler Axle Stabilizer Bearing (part# 32125LRB). It’s a neat little unit that installs in place of the stock seal and oil slinger in the trans. It has an integral roller bearing and seal that rides on the sealing surface of the axle. A good axle with a smooth and clean sealing surface is required because the roller bearing uses the old sealing surface and the new seal uses the very outer edge of the sealing surface, which will be rusty and dirty on a new axle. The extra axle I have was in good shape. Some sandpaper and some rubbing compound later, I had a nice bearing ans sealing surface. The bearing also has some gripping splines to keep it from spinning and an oiling hole that matches the oil feed hole on the trans.

I believe that I have found a “patch” for my current transmission problems. Thanks to Joe Dzwil, I was able to install a Techpak-Fitzall Chrysler Axle Stabilizer Bearing (part# 32125LRB). It’s a neat little unit that installs in place of the stock seal and oil slinger in the trans. It has an integral roller bearing and seal that rides on the sealing surface of the axle. A good axle with a smooth and clean sealing surface is required because the roller bearing uses the old sealing surface and the new seal uses the very outer edge of the sealing surface, which will be rusty and dirty on a new axle. The extra axle I have was in good shape. Some sandpaper and some rubbing compound later, I had a nice bearing ans sealing surface. The bearing also has some gripping splines to keep it from spinning and an oiling hole that matches the oil feed hole on the trans.

Before installing the bearing, I fully drained the transmission so that I could clean the surfaces properly. I did an “Ed Peters” to it by drilling out the hole in the square-shaped boss on the bottom of the differential housing, and tapping it with a 3/8″ NPT tap. Once it was drained, I plugged the hole with a brass pipe plug using solvent-safe PFTE thread tape (the yellow stuff). Getting good threads in the boss is tricky because it is slightly too large for the first 1/8″ or so. Use a slightly smaller drill bit than is required by the tap. Now I can change the fluid completely without pulling axles or removing the side cover.

Looks like the CSX will be at the SDAC Chicagoland meeting after all!

The CSX: August 26, 1999

by Russ Knize on Aug.26, 1999, under CSX

Well this new tranny appears to have a serious problem. I noticed a bad fluid leak coming from the left axle. I figured that maybe the seal went bad. So, I pulled the axle only to find the seal in good shape but the axle had a lot of play in the differential. I put a tight-fitting socket with an extension into the differential to see if the carrier bearings were shot. I could not make the differential move within the transmission case…it was very solid. Upon further inspection, I noticed that the axis on which the axle “wiggled” was on the axle shaft itself between the CV joint and the differential spline. It appears that the differential case is worn out. The axle shaft also has some wear on it. I have another axle (which actually came with the trans), which has no wear on the shaft at all. This axle was a bit more solid, but still pretty sloppy. Looks like I will have to pull the trans. ARGH!